Making A Lampworked Glass Bead

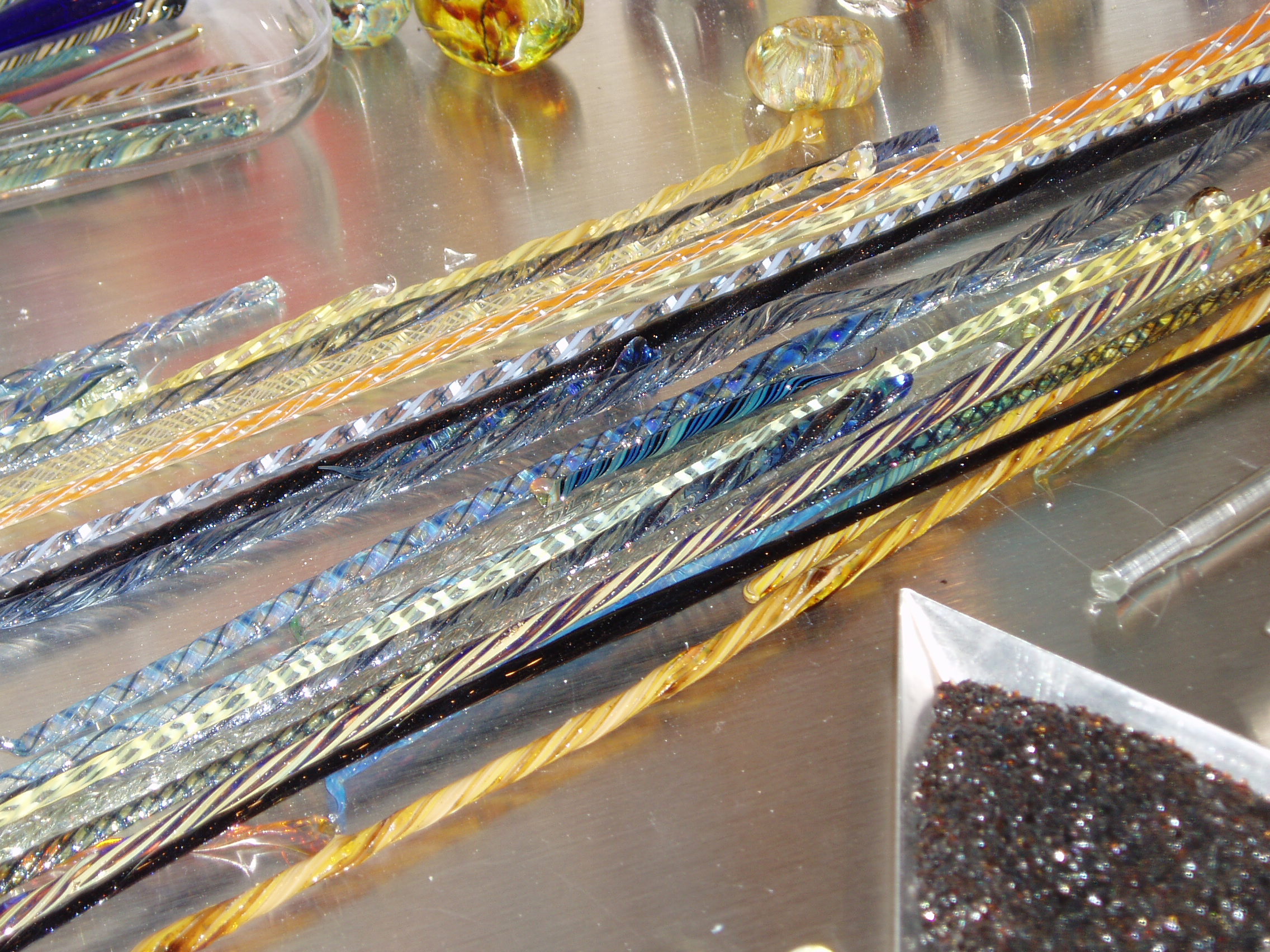

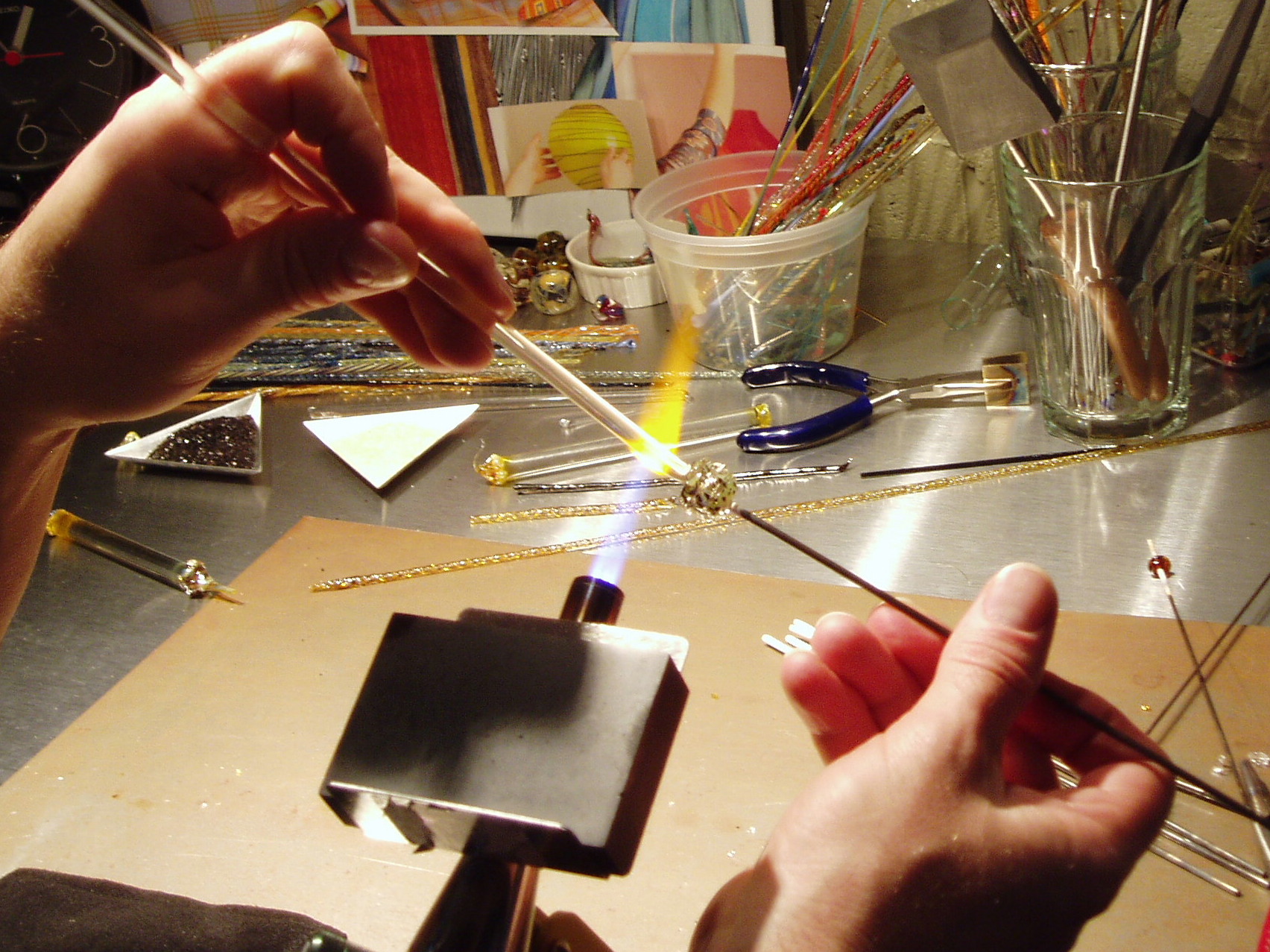

It starts with a stainless steel 3/32 rod dipped in bead release. Glass rods from Germany, Japan, America and Italy are then melted using a torch that combines natural gas and oxygen. The molten glass is wound around the rod and hand spun using gravity to form a perfectly round bead. Our beads are usually not round in order to fulfill our desire to keep our natural organic one a kind look. Our beads incorporate many natural materials such as copper, silver and gold into the base bead. We also use an extensive amount of frits (ground glass), enamels, and hand made stringers. Handmade stringers are a combination of different glasses, frits, and metals melted together and hand-pulled into thin rods of glass. These stringers are all one of a kind and many hours of endless combinations are used to achieve the desired result. All of these different materials are combined into making a one of a kind bead never to be exactly duplicated. After all of these combinations are melted onto the base bead the desired shape of the bead is established using stainless steal mashers or just plain gravity. They are then placed directly into a 965 degree kiln and over an 8 hour period are brought back down to room temperature. This process is called annealing and will add timeless durability and strength to the bead. All of our beads whether large or small are kiln annealed.